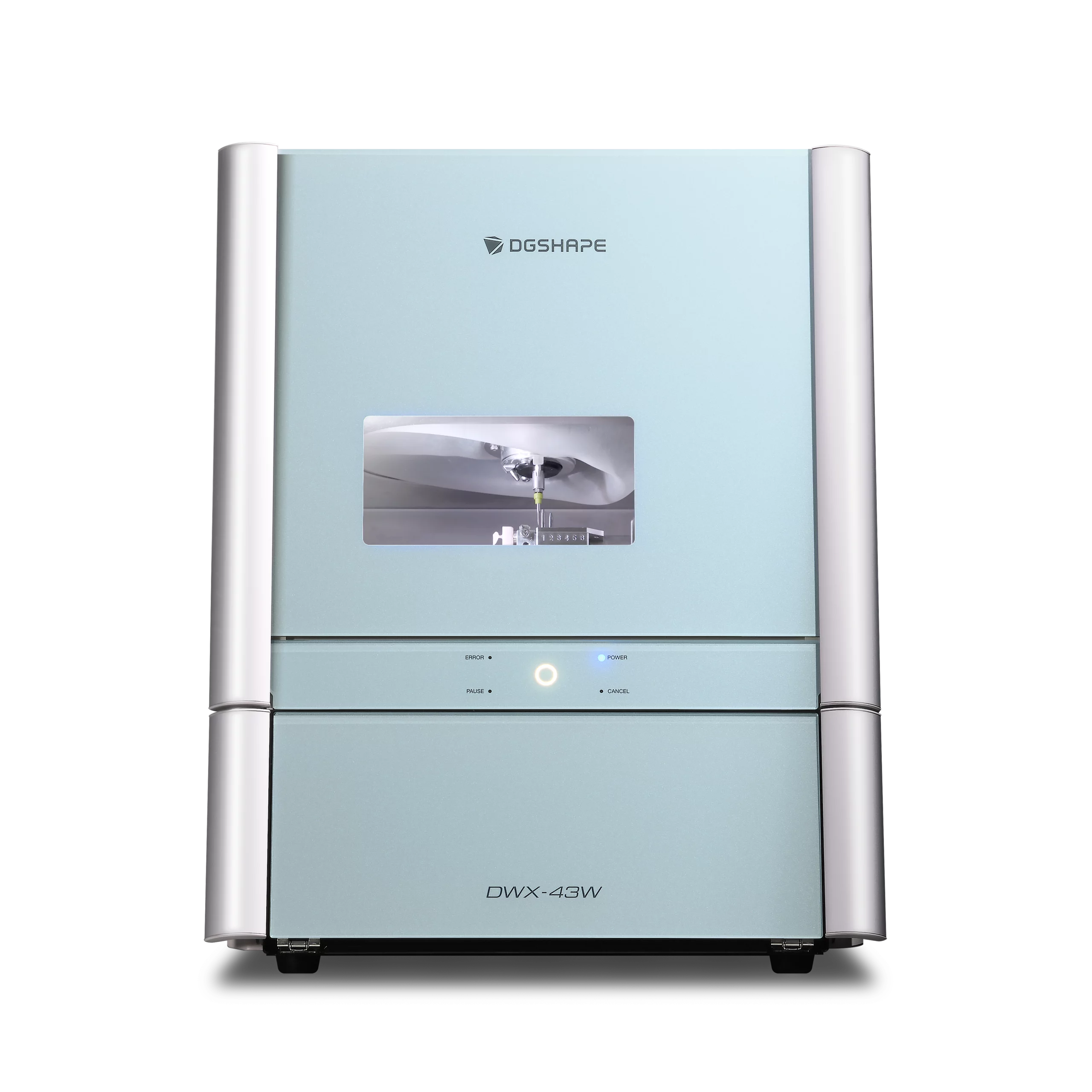

DWX-43W Wet milling machine

Increase your productivity and precision with the DWX-43W, the new versatile wet milling solution from industry leader DGSHAPE.

The DWX-43W can simultaneously mill up to six pen-shaped blocks with unparalleled accuracy.

Please note that all prices quoted are net prices, plus statutory value added tax.

26.950,00 € excl. VAT

Description

Increase your productivity and precision with the DWX-43W, the new versatile wet milling solution from industry leader DGSHAPE.

The DWX-43W can simultaneously mill up to six pen-shaped blocks with unparalleled accuracy.

It is compatible with a wide range of materials, including sintered zirconia, glass-ceramics, hybrid ceramics, PEEK, composite resins, PMMA and titanium alloys*, to meet all your in-house production requirements.

From crowns and veneers to custom titanium abutments (with optional attachments), the DWX-43W delivers consistent, high-quality results while streamlining workflows with automatic maintenance and user-friendly software.

Experience faster, smarter, and more versatile milling with the DWX-43W—the perfect blend of precision, performance, and affordability.

Problem-free in All laboratory and clinical workflows can be integrated

Laboratories

- Expand your production with a standalone wet grinding option suitable for materials such as sintered zirconium dioxide, glass ceramics, hybrid ceramics, PEEK, composite plastics, PMMA, and titanium alloys.

*An additional adapter is required to process titanium alloys. - Enjoy the same flexibility and high-quality performance you've come to expect from DGSHAPE dry grinders in wet grinding configurations, thanks to the open architecture.

- Expand your offer with on-demand production of highly esthetic dental restorations.

Clinics

- Offer your patients highly accurate same-day dental restorations - fabricated on a user-friendly machine and in a simplified workflow.

- The open architecture allows seamless integration with existing scanning devices.

- Reliable technology based on more than 30 years of experience with bench grinders

| Machinable materials* | Sintered zirconium dioxide, glass ceramics, hybrid ceramics, PEEK, composite plastics, PMMA, and titanium alloys* | |

| Loadable workpiece shape | Pen type | Max. 1.5 in. (width) x 0.8 in. (depth) x 0.8 in. (height) |

| Operating speed | XYZ axes | 6-1800 mm/min (0.24-70.9″/min) |

| Spindle speed | 15000-60000 1/min | |

| Rotation axis movement angle | A | ±360° |

| Number of integrated grinding wheels | 6. | |

| Mountable grinding wheel | Shaft diameter | 3 mm, special grinding tools |

| Required compressor specification (oil-free, with dryer) |

0.18 to 0.22 MPa or higher | |

| Air capacity | ||

| Interface | USB or Ethernet (10 BASE-T/100 BASE-TX auto-switching) | |

| Control command set | RML-1, NC code | |

| Energy supply | AC 100-240 V ± 10 %, 50/60 Hz (overvoltage category: II, IEC 60664-1), 2.1 A | |

| Power consumption | About 190 W | |

| Operating noise | In operation | 70 dB (A) or less (between cutting operations) |

| In standby | 48 dB (A) or less | |

| External dimensions | Width 482 mm (19 in.) x Depth 560 mm (22 in.) x Height 600 mm (23.6 in.) | |

| weight | 61 kg | |

| Installation environment | Use in closed rooms up to 2000 m above sea level, temperature: 5-28 °C (41-82 °F), humidity: 35-80 % rel. (no condensation), pollution degree: 2 (according to IEC 60664-1), temporary overvoltage: 1440 V, permanent overvoltage: 490 V | |

| Scope of delivery | Power cord, USB cable, manuals, DGSHAPE software package on CD, template for automatic correction, grinding tools, hexagon screwdriver, collet maintenance kit, etc. | |

Additional information

| Weight | 67000 g |

|---|

Only logged in customers who have purchased this product may leave a review.

Reviews

There are no reviews yet.